Clean air for a

bright future

RJM has supplied more than 35 ultra-low NOx CleanAirTM Burners to district-heating plants in Beijing and across China, contributing to the nationwide clean air initiatives.

The Clean Air Act of Greater China came into force in April 2017 to tackle the chronic levels of air pollution.

+ Discover

The Clean Air Act

The No. 1 priority of the act was to improve air quality in Beijing and then for the new legislation to be rolled out across all major Chinese cities. It effectively outlawed the use of coal-fired plant and required gas-fired industrial burners of the type used in factories and district heating plants to meet the new NOx emission limit of 30mg/Nm³, equivalent to 15ppm. To satisfy this demand, RJM developed a state-of-the-art, ultra-low NOx burner that could be custom-sized to suit any load requirement from 10MWth to 100MWth. It was also designed to operate with as low as 1% excess O², making the plant more efficient and therefore able to deliver more heat for a given fuel input. This is something that competitor products could not match as they need to operate at around 3% – 4% O² if they are to avoid issues with combustion stability.

First installation in Fengtai district

RJM’s first major project in China using its new ultra-low NOx gas-fired CleanAir Burner™ was the retro-fitment of nine units onto three 116MWth industrial hot water boilers that form part of a district heating scheme in the Fengtai district of Beijing. These three industrial hot water boilers are generally used as a back-up resource during the particularly cold winter months when demand for hot water and heating is at its greatest. Following a detailed site survey carried out in March 2016 by RJM’s engineers, RJM then applied its sophisticated CFD modelling capabilities to ensure the low NOx threshold could be met, working on the principle that by diverting around 20% of the flue gases back through the burner, this would lower peak flame temperatures and thus reduce the formation of NOx – this effective NOx emissions reduction technology is known as Flue Gas Recirculation (FGR).

A spectacular NOx reduction

Installed in 2016, with commissioning and optimisation carried out by RJM and its local agent HKL Global, these boilers are now operating reliably and safely in automatic mode, across the entire boiler load range and deliver NOx emission levels of less than 30 mg/Nm³ (corrected to 3.5% O²) and CO emissions of less than 10 mg/Nm³(corrected to 3.5% O²) with a measured boiler O² of 1%. With NOx emissions originally at 120mg/Nm³, this represents a spectacular NOx reduction of over 75%.

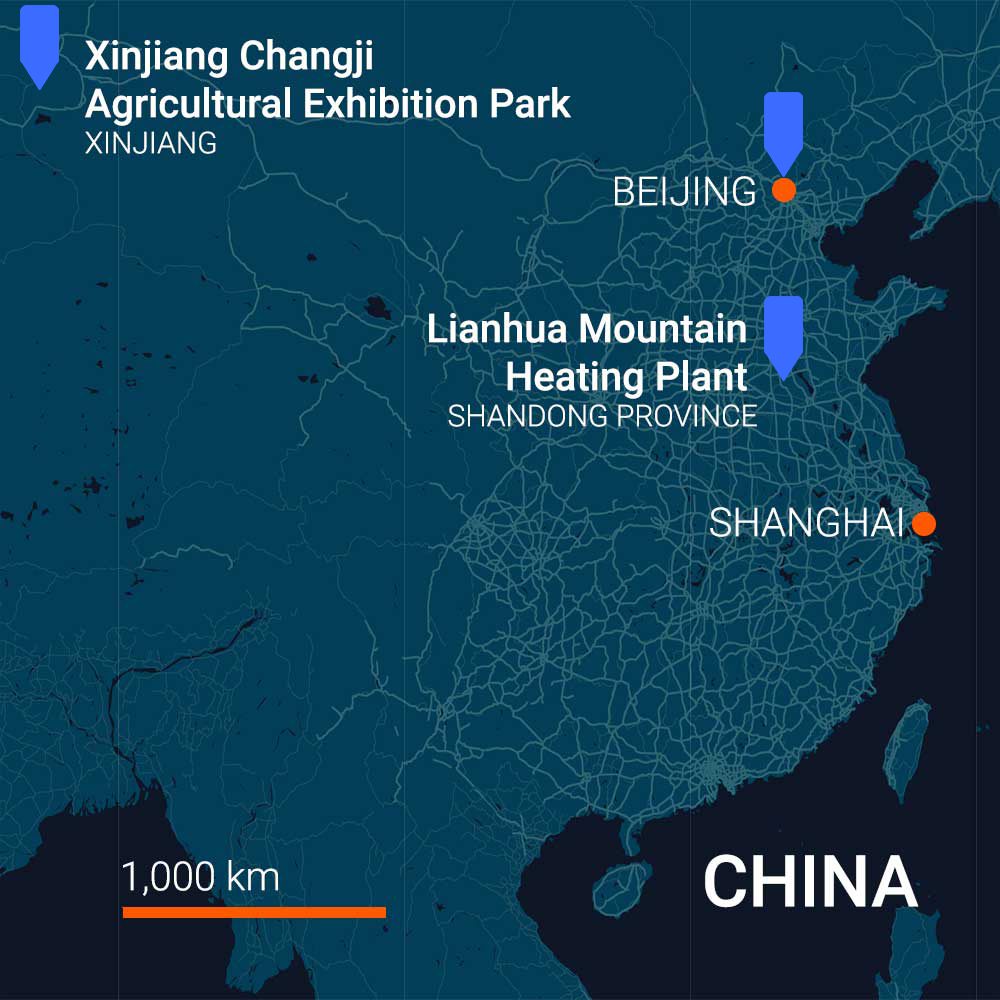

Since that first installation, RJM has supplied a further 26 of its ultra-low NOx CleanAir Burners™ into China, with the two most recent installations far beyond Beijing at Linhua Mountain Resort, 400kms south of Beijing and at Changji City Agricultural Exhibition Park, part of a “National Clean City”.

Close X

The RJM CleanAir Burner™

provides customers with:

<30mg/Nm3 NOx at 1% excess O2

for maximum efficiency

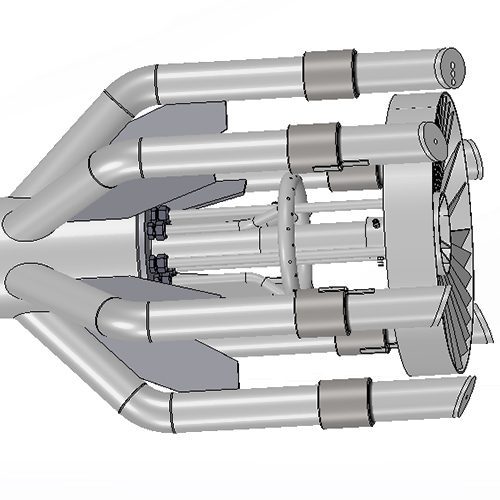

Cutting-edge CFD modelling is utilised in the R&D phase and for more challenging projects.

CAD/CAM tools enable RJM to optimise mechanical design and manufacture processes.

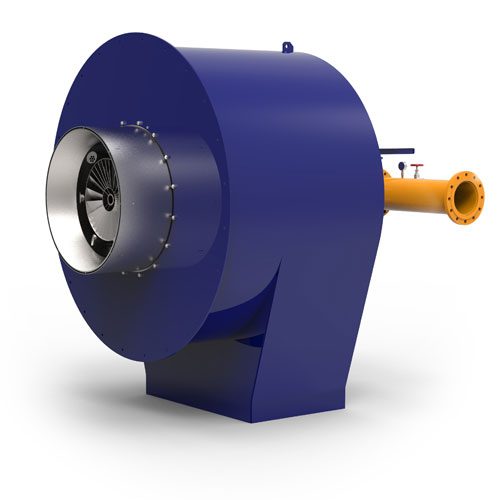

RJM CleanAir Burner™—the final high-quality product ready for exporting to global markets.

Technical Specifications

RJM CleanAir Burner™

+ Discover

Ultra-Low NOx CleanAir Burners™

- 20-100 MW

- NOx < 60mg/Nm³ without FGR

- NOx < 30mg/Nm³ with FGR

Low NOx CleanAir Burners™

- 20-100 MW

- NOx < 100mg/Nm³ without FGR

- NOx < 60mg/Nm³ with FGR

- State-of-the-art technology

- NOx < 30mg/Nm³ / 15ppm with FGR

- NOx < 60mg/Nm³ / 60ppm without FGR

- Pre-mix technology to create “internal” FGR

- Tangential and radial pokers create fuel staging

- Circumferentially-staged swirler creates deep flame staging

- Steel throat and stainless quarl provides optimal flame shape

without degradation over time

Low NOx CleanAir Burners™

- Versatile compact flame that can be adjusted to fit any boiler

- Modular design with flexibility to suit all boiler types

- No refractory or tile

- Maintenance-free design

- High quality construction

- Robust and durable design

- High turn-down ratios for wide range of boiler operations

- No combustion-induced boiler vibrations

- Flame stability at low excess air rates for reliable, energy-efficient boiler operation

Close X

Case study – Beijing

The first ultra-low

NOx <30mg/Nm³

116MW boiler in China

A new vision for lower emissions

RJM was contracted by HKL Global to supply nine RJM CleanAir Burners™ (three per boiler) to reduce NOx on an ageing district heating facility owned and operating by China Huadian, one of China’s “Big 5” energy companies.

The old Oilon low-NOx gas burners were replaced with new RJM CleanAir Burners™ and an RJM-designed Flue Gas Recirculation (FGR) system was installed. Emissions of NOx and CO were reduced by >75% and >95%, respectively.

Original performance:

RJM upgrade performance:

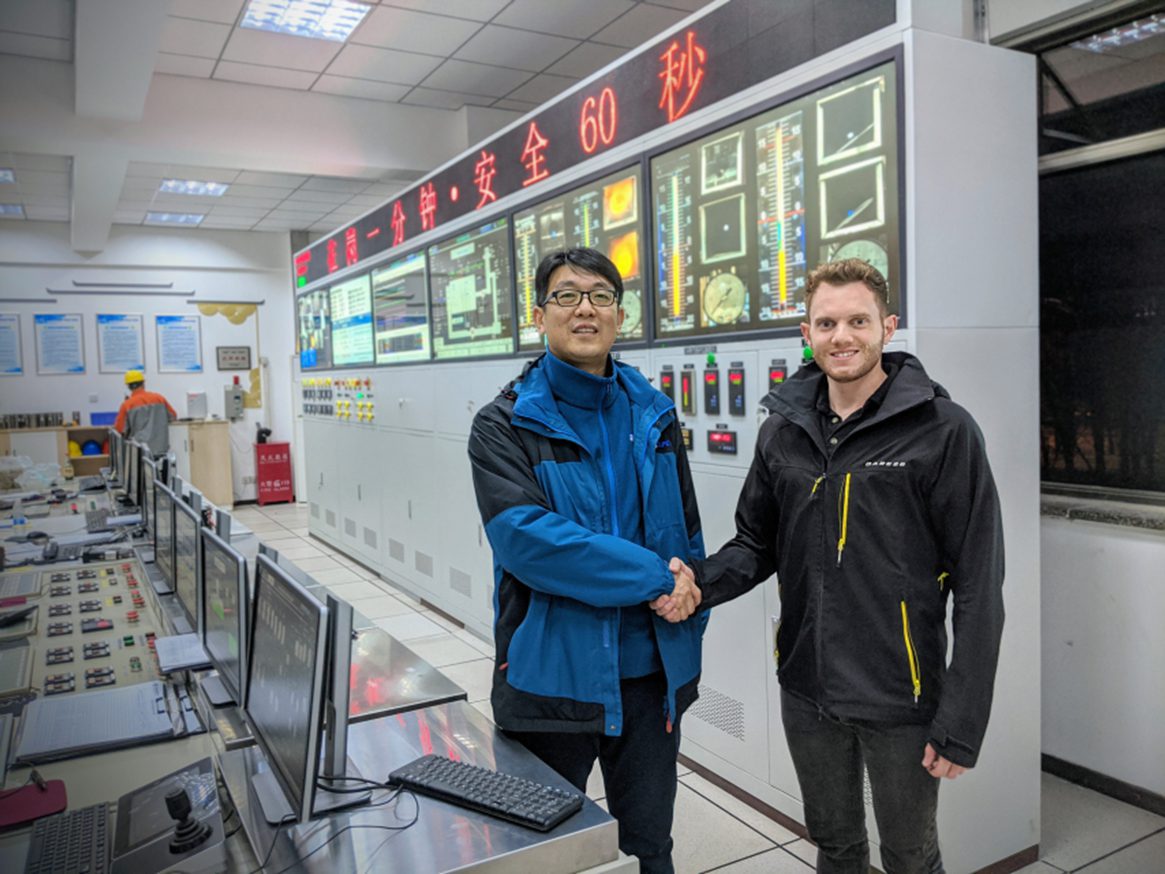

Partnership in action

RJM appointed HKL Global to act as its agent in the Chinese industrial burner market in 2016. The two companies have been working closely together since then, building up sales of the CleanAir Burner™ within Beijing and now rolling out this unit into greater China.

![]() RJM CleanAir Burner™ installations

RJM CleanAir Burner™ installations

Beijing relies on municipal district heating schemes to produce hot water that is used to heat buildings during the ‘Winter Heating Season’. RJM has installed 35 of its gas-fired, ultra-low NOx CleanAir BurnersTM in the capital, with capacities ranging from 40-100 tonnes of hot water per hour.

To maintain the blue skies in the capital, the Beijing government has made great efforts to decrease major pollutant sources.

Yu Jianhua, Chief Engineer,

Environmental Protection Bureau

Partnership in action

RJM appointed HKL Global to act as its

agent in the Chinese industrial burner

market in 2016. The two companies have

been working closely together since then,

building up sales of the CleanAir Burner™

within Beijing and now rolling out this unit

into greater China.

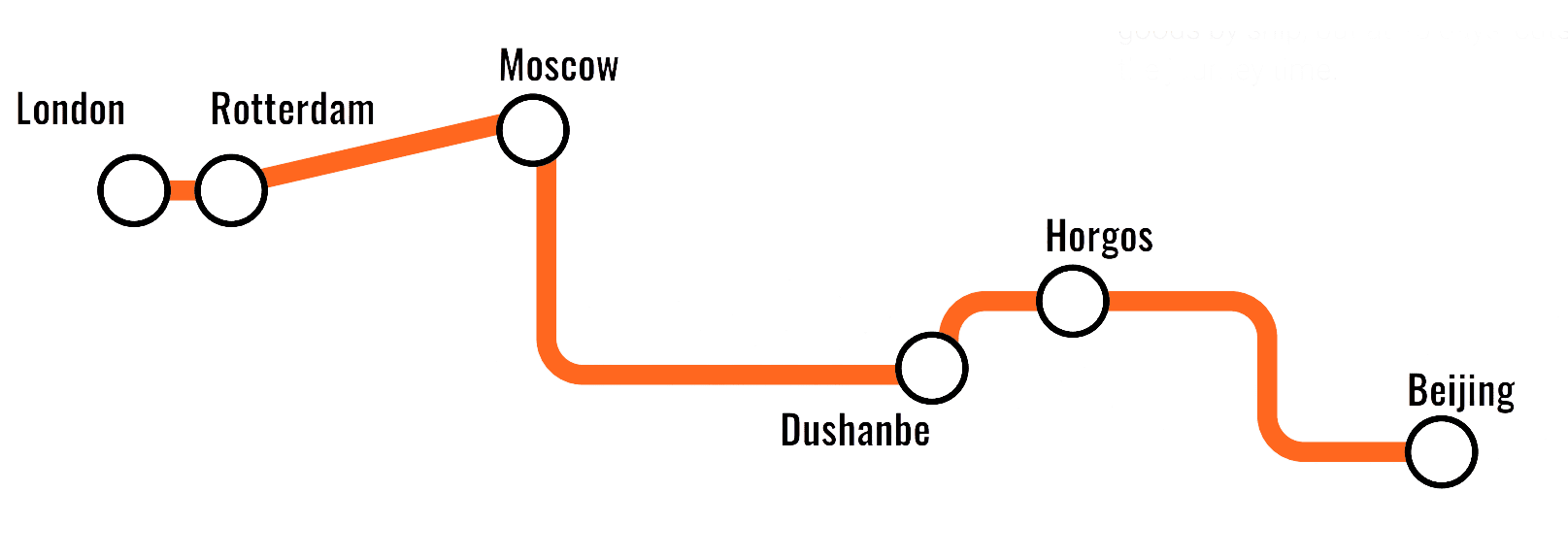

Low-carbon

transport

From the UK to China by rail

We send our burners out to China on the new ‘Silk Road’ rail link connecting Europe with Asia.

Benefits

RJM’s modular CleanAir Burners™ have been designed to be transported by rail. This offers a broadly comparable carbon footprint to sending goods by ship, but at 15 days, cuts two weeks off the journey time.

Projects

RJM CleanAir Burner™ retrofit to cut air pollution

China

Huadian, Beijing

Key challenges

3 x 116MWth boilers require retrofit to meet NOx levels below 30mg/Nm3 as mandated by the new China Clean Air Act.

Oil & gas-fired NOx reduction project

Netherlands

Clauscentrale Unit A,

Essent Energie

Key challenges

To reduce NOx on gas <200mg/Nm3 and on oil to <400 mg/Nm3 with no detrimental loss in efficiency, as well as reducing furnace vibration and high metal temperatures in the reheater.

New RJM CleanAir Burner™ install to cut air pollution

China

Huayuan 70MWth boilers, Beijing

Key challenges

RJM was tasked with providing new Ultra-Low NOx CleanAir Burners™ to meet a NOx threshold of 30mg/Nm3 or less. These were fitted to six new Taishan 70MWth single burner boilers (one per unit) for Huayuan, at one of its district heating plants in Beijing.

70MWth coal slurry-to-natural gas conversion

China

Jinan

Key challenges

To convert the boiler from coal slurry firing to natural gas firing and reduce NOx emissions to <15ppm at 3.5% O2 with up to 30% FGR.